Fully continuous pyrolysis plant can recycle some solid waste to renewable energy. With the development of maturity of the pyrolysis technology, fully continuous pyrolysis plant is increasingly welcomed by various countries because of its advantages of high environmental protection, high degree of automation and high oil yield. The following is the detailed description of the fully continuous pyrolysis plant.

Raw materials suitable forfully continuous pyrolysis plant

The raw materials which can be treated by the fully continuous pyrolysis plant include waste tires, waste plastics, waste rubber, oil sludge and so on. Generally speaking, the main raw materials to be treated are waste tires, waste plastics and oil sludge. Here’s the list of oil yield about common waste tires and plastics. Oil sludge needs to see the specific composition ratio to determine the oil yield.

The oil yield of common waste tires and plastics obtained from fully continuous pyrolysis plant

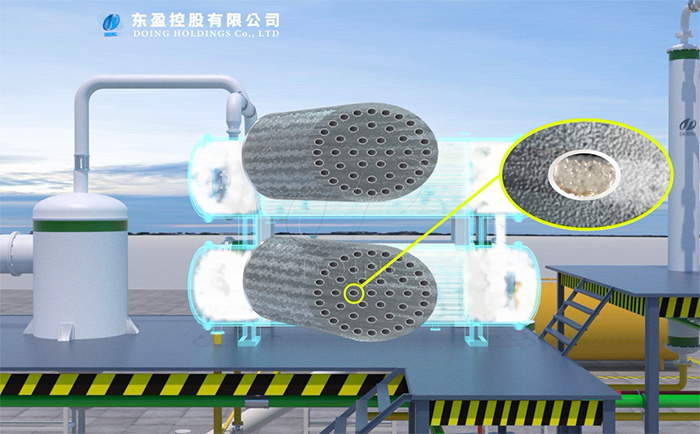

Main components of fully continuous pyrolysis plant

DOING Group’s fully continuous pyrolysis plant mainly includes accurate calculated pyrolysis system, PLC control system, condensing system, desulfurization tower, unique slagging system, etc. The following figure shows a 3D model of the fully continuous pyrolysis plant.

The main workflow of fully continuous pyrolysis plant

1. Collect enough waste tires or waste plastics.

2. The collected waste tires were broken into small pieces of 2-3 cm by a tire shredder. If your raw material is waste plastics, they needed be broken into small pieces by plastic crusher.

3. Feed the raw material crumbs into the pyrolysis reactor through a sealed screw pusher .

4. Heat the pyrolysis reactor, when the temperature reaches a certain level, oil gas will be cracked.

5. Cracked oil gas entering the condensing system will liquefy into heavy oil and fall into the oil tank.

6. Desulphurization and denitrification of tail gas are carried out and pollution-free gases are finally discharged.

7.The carbon black obtained in pyrolysis reactor is discharged outside the furnace through a sealed screw conveyor.

Technical parameters of fully continuous pyrolysis plant

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

Unique advantages of fully continuous pyrolysis plant

Under the synergistic action of these components, the fully continuous pyrolysis plant has the following advantages.

1. Accurate calculation system can ensure that the raw material can be fully cracked to improve the oil yield.

2. Fully continuous pyrolysis plant can achieve continuously feed, continuously discharge slag 24 hours a day, and it has higherproduction efficiency.

3. Fully automatic operation can be achieved by PLC control system. That is to say, little manpower can complete the operationof the fully continuous pyrolysis plant.

4. Fully continuous pyrolysis plant is equipped with an efficient tubular condensing system to increase oil production.

Final products and applications from fully continuous pyrolysis plant

If your raw materials are waste tyres or waste plastics, you mainly get fuel oil and carbon black which have widely uses in our daily life.

1. Fuel oil

According to use, fuel oil can be divided into marine fuel oil, furnace fuel oil and other fuel oils. The fuel oil obtained from fully continuous pyrolysis plant can be widely used in marine boiler fuels, furnace fuels, metallurgical furnaces, and other industrial furnace fuels, such as used in steel factory, cement factory, glass factory, etc.

2. Carbon black

Carbon black is mainly used for pressure ball combustion and refined milling. The refined flour can be used for new tires, rubber soles and various pigments.

No comments yet.